Simulate your cold chain with our software platform

Digital Twins

for the Cold Chain

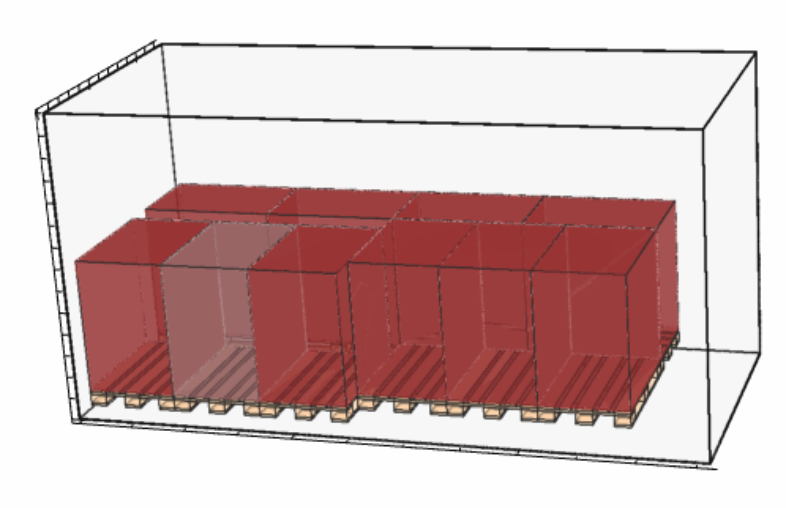

Thermal Packaging

... lets you build a digital version of any physical insulated shipping system.

SmartCAE Software & Service

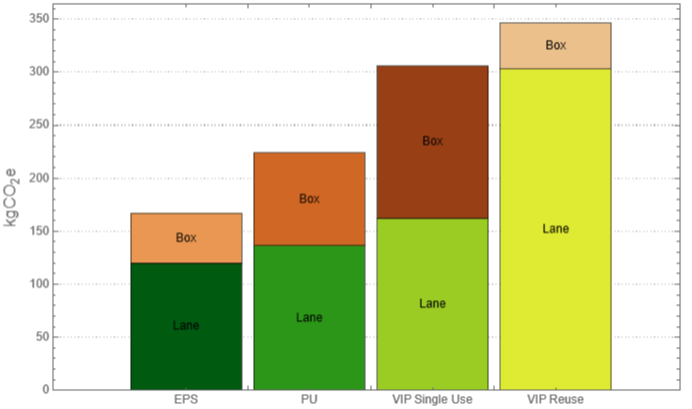

Carbon Footprint

Calculate the carbon fooprint generated from your shipping processes.

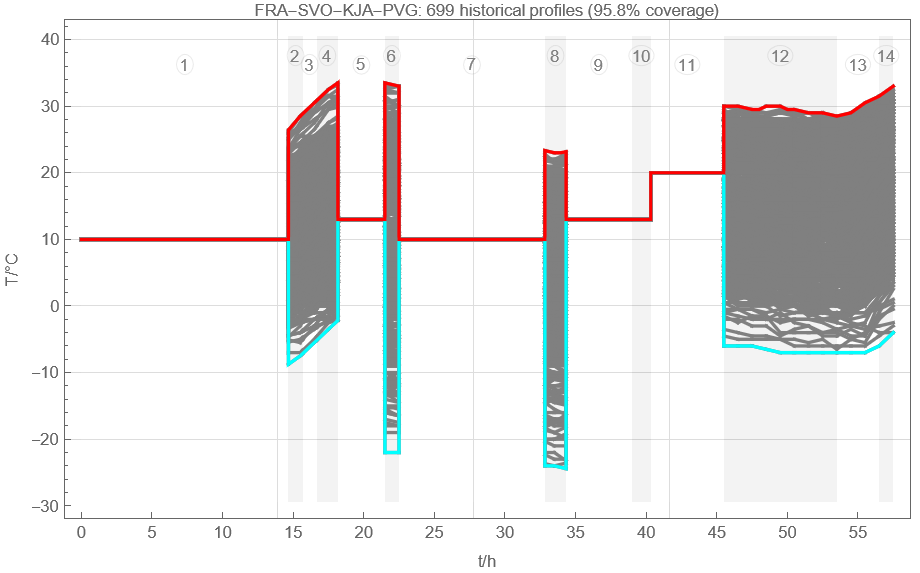

Lane Profiles

... makes it easy to profile ambient conditions on global shipping lanes.

Data Tools

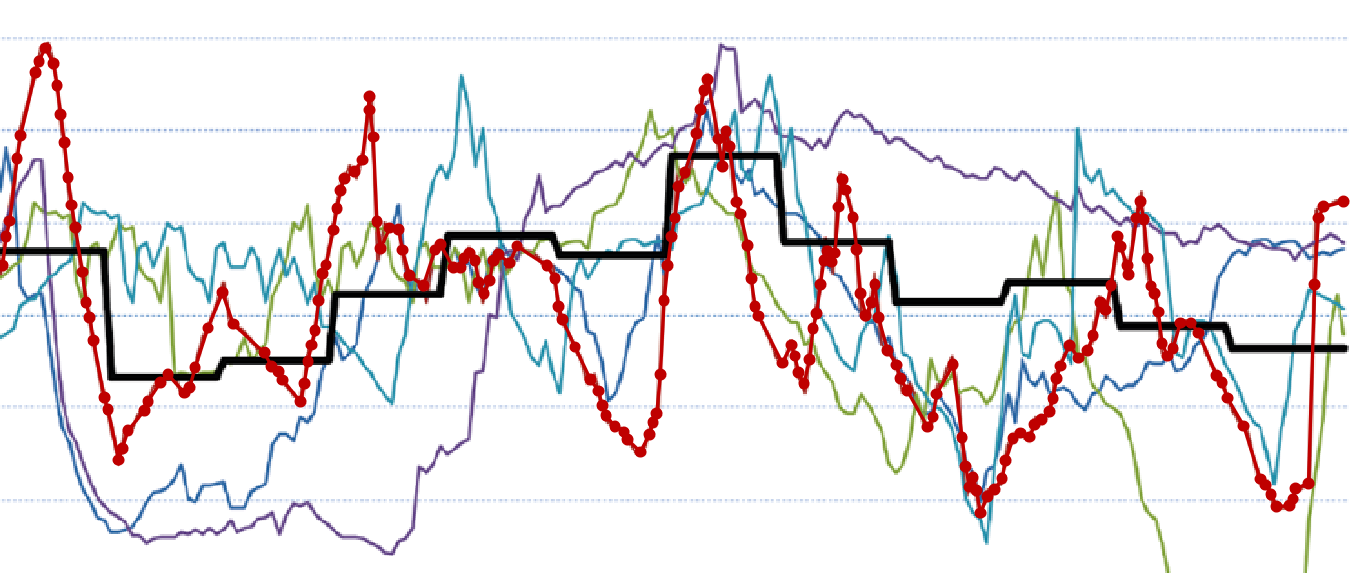

... digitize data from PDFs and images, process and compare logger data.

Ocean Service

We quantify the effect of power-offs on temperature sensitive goods for your specifc setup.

SmartCAE provides software and service solutions for

Temperature Controlled Logistics.

Use our solutions to perfect your cold chain

with the right measures.

Let's be faster, more accurate, more resilient, more cost-efficient, and smart!

With our Digtal Cold Chain you can:

-

calculate lane-specific product lifetimes,

-

quantify risk for temperature excursions,

-

optimize total cost of ownership,

-

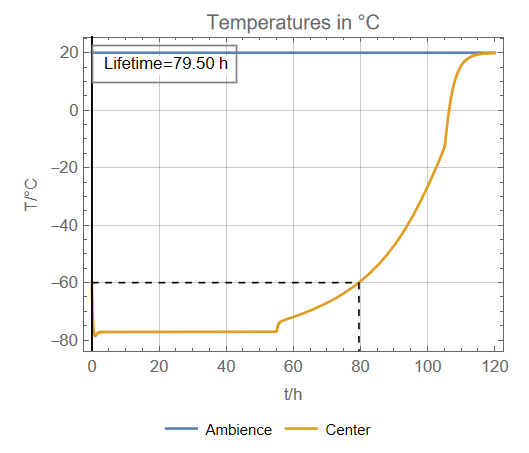

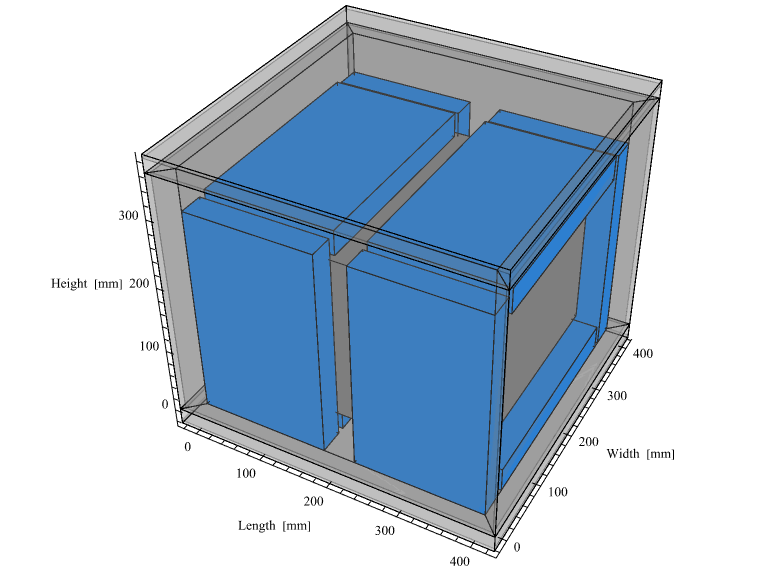

simulate digital twins of your shippers,

-

and create data-based ambient temperature profiles

with just a few clicks.

Be smart & fast: Go digital!

Make Use of Existing Data

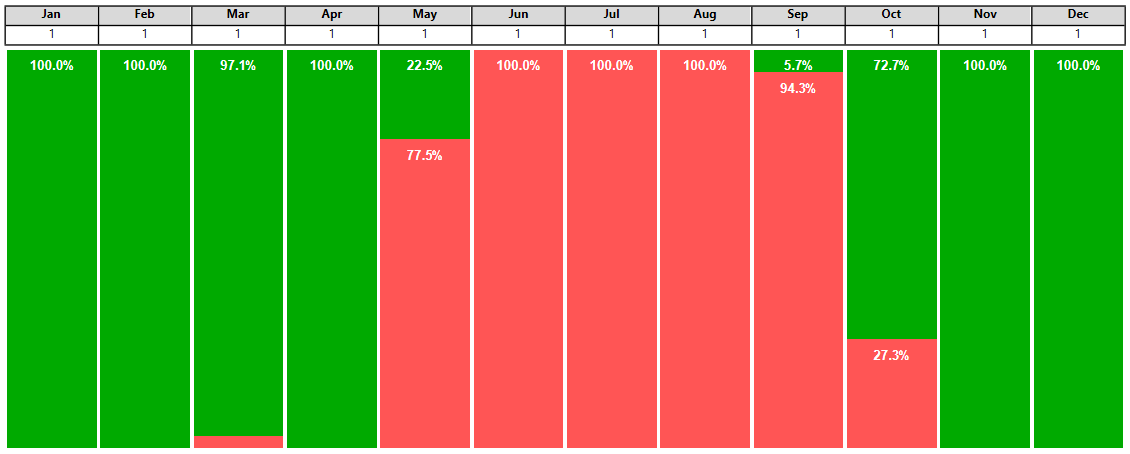

Weather data have been recorded for decades. We use these in combination with mathematical models, to create realistic ambient temperature profiles for shipping routes.

Minimize Resources

Accelerate qualification processes through simulations. Save time, costs, and materials by avoiding unnecessary test shipments and test measurements. Only test what remains necessary, after exploring everything digitally.

Prevent Temperature Excursions

25% of medical shipments are spoiled on the way to their destination. Some because of freezing, some because of overheating. Simulations help to fully understand the risks of packaging material and lane, and prevent temperature excursions in the field.

Quantify Risks

Risks on shipping lanes are quantifiable. They are based on numerous factors, such as packaging designs, ambient temperatures, delays, seasons, and more. With simulation tools, quantifying these risks is at your fingertips.

Our all-time Classics

Check out our bestselling software modules below.

How does it work?

Simulation is the data-driven way forward to assess whether your product will survive the shipping. Check out our explanatory video for a taste of what simulation can do for you in temperature-controlled logistics.

Questions?

We are happy to help you with any questions you may have.

If you want to get a first hands-on experience of our entire software, we also offer free 30 days trial licenses.